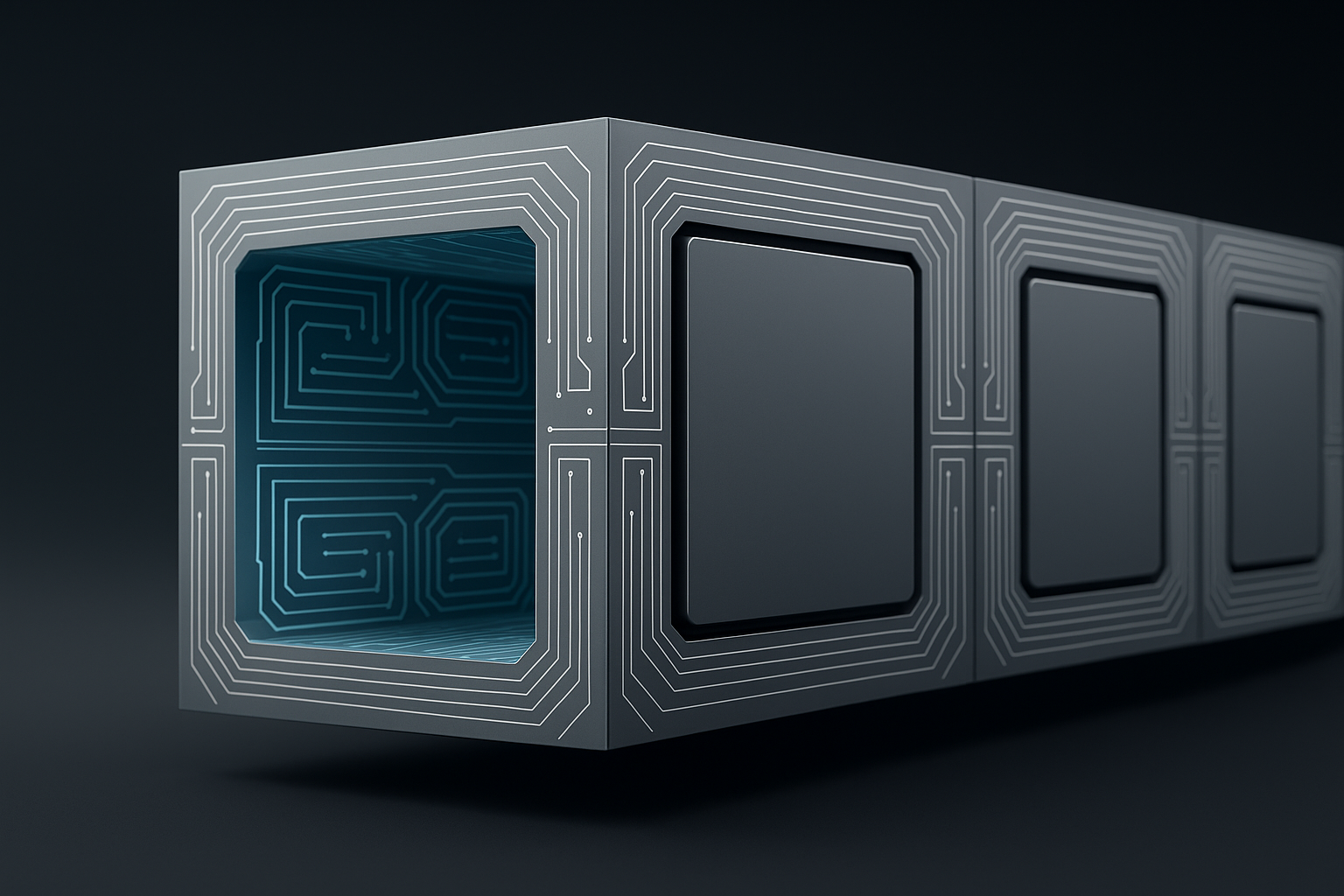

Embedded liquid channels

Precision channels route coolant where it’s needed most, scaling from device to rack.

ColdBoard integrates liquid and vapor cooling inside the PCB to reduce size and cost and unlock new performance envelopes.

ColdBoard turns the printed circuit board into an active cooling surface. Liquid channels and optional vapor chambers are embedded into the substrate. Heat moves directly from components into coolant, reducing junction temperatures and enabling higher sustained power.

Precision channels route coolant where it’s needed most, scaling from device to rack.

Lateral spreading reduces hot spots and equalizes thermal density.

Couples heat into fluid layers while preserving electrical isolation.

Wrap edges or form tube-like conduits to route heat and fluids efficiently.

Performance depends on design and duty cycle; validated with your hardware during evaluation.

Avionics, radar, C4ISR, directed energy, rugged compute.

GPUs & accelerators gated by thermal envelopes.

EV inverters, chargers, and industrial drives.

5G/6G radios, edge AI, dense routers.

Time-bound evaluation for fit and performance; typical 3–5 years.

Royalty or lump-sum structures with tech transfer support.

Design guides and collaboration with your E/M teams.

Defense via selective sovereign licensing; commercial via EMS/AME partners.

Some descriptions are simplified; full details under NDA.

Email info@coldboard.com or use the form.